OEM Repair Guidelines are crucial for maintaining vehicle quality, emphasizing structural repair precision. These guidelines provide automotive technicians with a detailed framework to ensure every component is replaced or repaired accurately, preserving the vehicle's integrity, safety, and performance. Structural repair precision, achieved through meticulous techniques and advanced technology, is vital for collision damage repair and ensures vehicles meet OEM standards. This approach offers significant advantages, including enhanced safety, structural stability, aesthetic appeal, and reduced long-term costs for both manufacturers and owners.

Structural repair precision is a cornerstone of modern automotive maintenance, aligning perfectly with Original Equipment Manufacturer (OEM) repair guidelines. This article delves into the intricate relationship between these two elements, exploring how precise structural repairs ensure vehicle safety and reliability. We’ll examine OEM standards as a quality foundation, uncover the vital role of precision in meeting those benchmarks, and highlight the significant benefits and impact of this alignment on both repair outcomes and customer satisfaction.

- Understanding OEM Repair Guidelines: A Foundation for Quality

- The Role of Structural Repair Precision in Achieving OEM Standards

- Benefits and Impact: When Precision Meets Guidelines

Understanding OEM Repair Guidelines: A Foundation for Quality

Understanding OEM Repair Guidelines: A Foundation for Quality

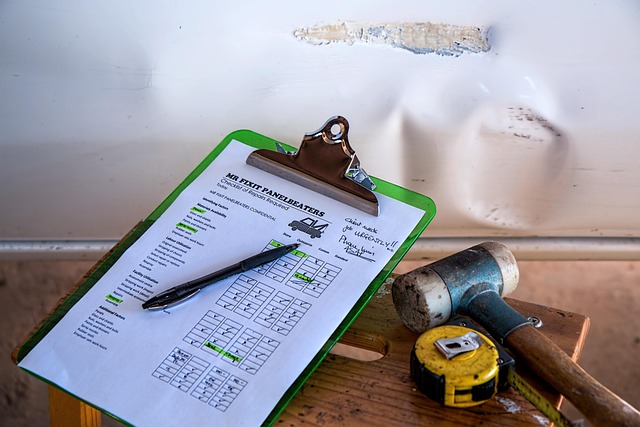

OEM (Original Equipment Manufacturer) repair guidelines serve as a cornerstone for ensuring that vehicle repairs meet the highest standards. These guidelines are meticulously designed to maintain the integrity, safety, and performance of vehicles. When it comes to structural repair precision, these guidelines provide a clear framework for technicians to follow. By adhering to OEM specifications, automotive repair specialists can guarantee that every component is replaced or repaired with the utmost care and accuracy.

This meticulous approach extends beyond mere replacement to encompass various aspects of vehicle body repair and paint repair. The guidelines specify precise measurements, tolerances, and techniques to ensure that structural repairs are as close to the original manufacturing standards as possible. This level of precision not only preserves the vehicle’s aesthetic appeal but also ensures its longevity and safety on the road.

The Role of Structural Repair Precision in Achieving OEM Standards

Structural repair precision plays a pivotal role in achieving Original Equipment Manufacturer (OEM) standards for automotive body work. It involves meticulous techniques and advanced technology to ensure that damaged components are repaired or replaced with utmost accuracy, matching the exact specifications set by the vehicle manufacturer. This is particularly crucial in cases of collision damage repair, where even minor discrepancies can compromise the structural integrity and safety of the vehicle.

By adhering to strict guidelines and employing specialized tools, skilled technicians can perform precise repairs that not only restore the vehicle’s aesthetic appeal but also maintain its overall performance and reliability. This level of precision is essential for auto maintenance, as it guarantees that every repair aligns seamlessly with the OEM’s vision, enhancing the vehicle’s longevity and safety on the road.

Benefits and Impact: When Precision Meets Guidelines

When structural repair precision aligns with OEM (Original Equipment Manufacturer) guidelines, it brings about a multitude of benefits for both manufacturers and consumers. By adhering to these stringent standards, car repair services can ensure that repairs are not just visually appealing but also functionally sound. This meticulous approach guarantees that every component is accurately replaced or reconstructed, maintaining the integrity and overall quality of the vehicle.

The impact of this precision extends beyond mere aesthetics. It enhances safety by ensuring structural stability and reduces the risk of future damage. Moreover, it saves time and resources in the long run as repairs are completed efficiently, minimizing the need for costly revisions. Even minor details like dent removal are handled with precision, contributing to a seamless restoration that meets or exceeds OEM expectations.

Structural repair precision is not just a best practice; it’s the linchpin that connects repair quality with original equipment manufacturer (OEM) guidelines. By adhering to these precise standards, repair technicians can ensure superior vehicle performance and longevity. This alignment between structural repair precision and OEM repairs results in benefits such as enhanced safety, improved aesthetics, and cost-effectiveness for both repair shops and vehicle owners. Embracing these guidelines is crucial for maintaining the integrity of vehicles and fostering a robust automotive industry.